Using ALeader AOI for various applications

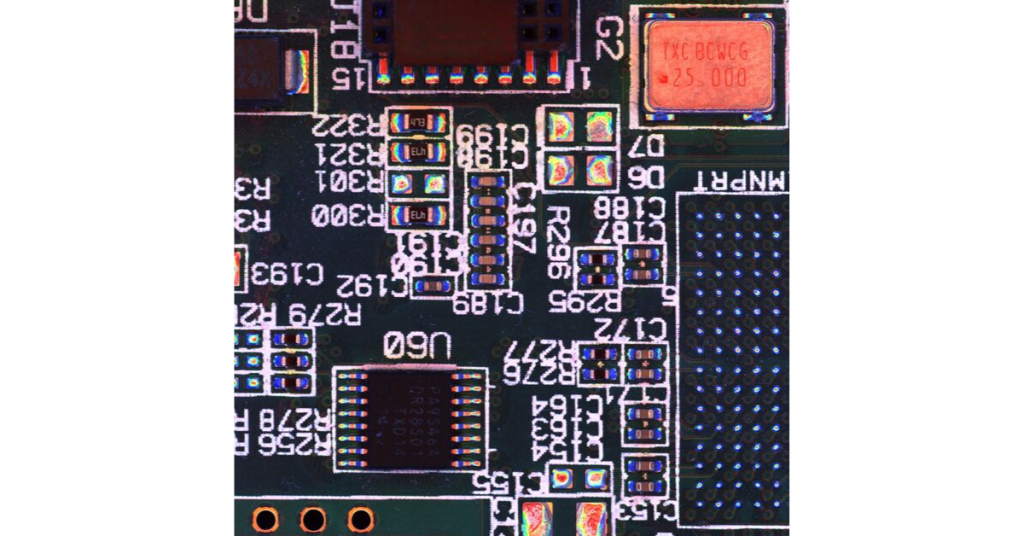

There is a common situation in the customer site when the same AOI is required to inspect PCBs in a standard after-reflow mode and, at the same time, be able to test the boards, for instance, after glue. The main challenge for AOI system in this situation is that the big difference in lighting required to effectively detect pad glue contamination and the standard light configuration for the reflowed solder joint inspection.

As many AOI systems in the market have been originally designed for after reflow application, those machines have some capability to inspect the glue, but performance for such application is usually limited and required log program tuning and in some cases even the HW changes.

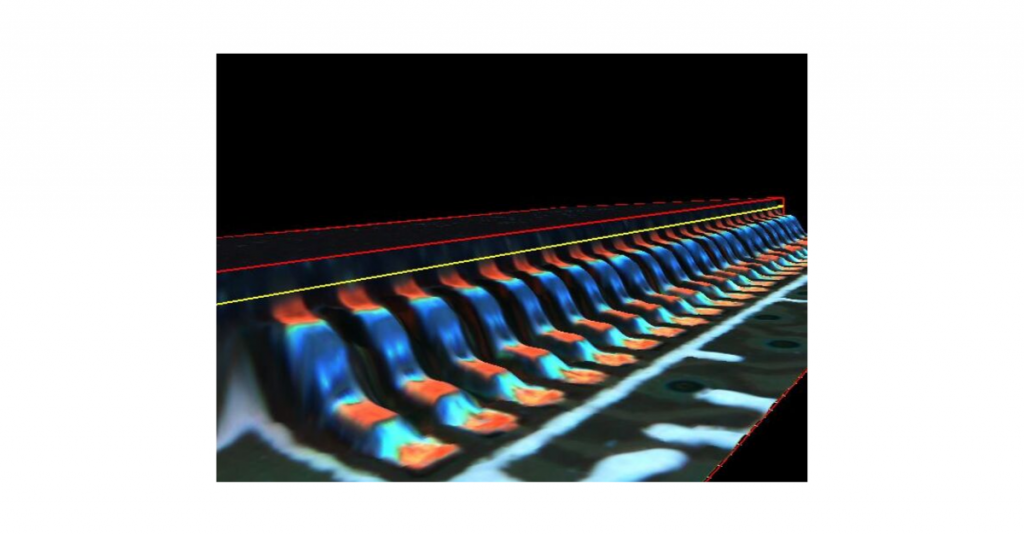

ALeader ALD i3D systems have been originally designed to be run in various applications and answer customer needs in the best way. The unique design of the ALeader system light tower and the smart control mechanism allow to give an appropriate light without need in any HW changes. More than that, there is no need in any specific program adaptations and adjustment.

ALeader AOI is preserving the light configuration for different kind applications – after reflow, glue, after wave and more. The user only need to define the mode during the program creation. Operator loads the program and system automatically uses appropriate lighting.

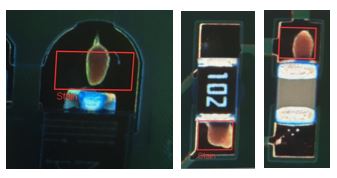

In the picture: Pad Glue contamination detected by ALeader ALD7720S i3D Inline AOI in the glue mode