MPE Testimonial

Keith Chamberlain, Sales Director at MPE Electronics

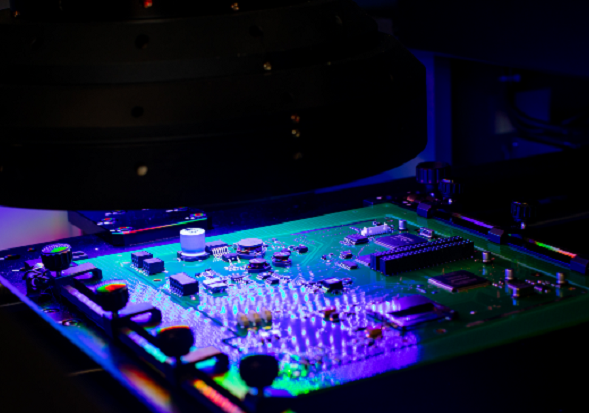

Based in Uckfield within the beautiful region of East Sussex MPE are a specialist in PCB Assembly and Product Assembly and so with close customer liaison are able to manufacture their client’s products delivering a fully engineered, manufactured and tested units.

MPE’s history goes back to 1988 when Directors Keith Chamberlain and Frank George ran a successful sub-contract company named Phoenix Electronics which merged in the early 1990’s with another local manufacturer named METEC. This merger resulted in the new company ‘MPE’ having both excellence in PCB and wiring harness and chassis assembly.

Keith Chamberlain comments “our business has grown steadily over the years to the point now where we have 4 surface mount lines comprising 4 pick and place machines, 4 ovens, Vapour Phase capability and various AOI and general testing equipment. However, despite this extensive list of plant, we found that due to improvements in technology, our older AOI machines were not able to maintain pace with the ramp up in production and were on the edge of their capabilities regarding false calls and therefore possible escapes”

Aleader have a unique approach to the way they utilise camera technology and the algorithms required to find faults that historically result in a huge investment in time to produce a program while resulting in high levels of false calls.

“False calls were the bane of our life” continues Chamberlain “we felt we needed to leave the calls at a higher level to ensure that the machine operator could spend time manually confirming that the faults were in fact not genuine – while this ensured that we were producing a good quality product, the overhead of the additional inspection and the toll on the operator in terms of time and eye-strain was not supportable”

The team at MPE went to market and evaluated a number of suppliers, with a few key performance parameters in mind “we needed to have the ability to find the general process faults such as lifted leads, insufficient solder joints, bridging, device marking and so on. We wanted to get the level of false calls to a minimum while at the same time having a machine which is easy to program” explains Chamberlain “the Aleader ticked all of this boxes and more, as well as having a very competitive price!”

After successful installation by Europlacer and around a year’s experience with the new machine, MPE found that due to continued capacity improvements and phasing out older AOI equipment a second machine was required “with the excellent support from the team at Europlacer and the superb performance of the initial Aleader, buying a second one was an easy decision and we continue to be delighted with both Aleader and Europlacer” concludes Chamberlain.