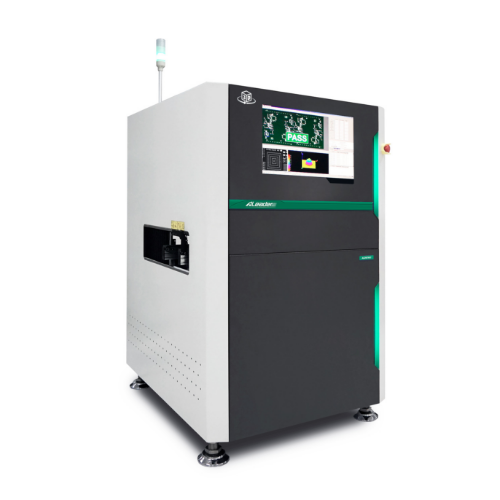

SPI Machine- ALD6700S

Simultaneous 2D and 3D inspection guarantees full inspection coverage with the most accurate measurement of height, area and volume of the paste deposits

Excellent – high resolution image, generated by the high speed camera and the unique lighting system, clearly differentiate the pastes, pads, silkscreen and the board.

Innovative – automatic warpage compensation and measurement floor recognition method based on the color filter. Effective combination of the high quality color 2D image and large 3D measurement range allows an easy identification of the pads as a zero level for the paste height measurement. The method completely eliminates influence of the PCB warpage. The process is completely automatic and no actions from user are required.

Precise – height measurement based on Phase Measurement Profilometry (PMP). Bi-directional phase shifting projection system ensures accurate and noise resistant measurement of the paste height and volume.

The ALEADER ALD6700S represents a new standard in solder paste inspection systems for SMT lines that demand the highest levels of precision, speed, and reliability. With its bi-directional phase-shifted projection and real-time warpage compensation, it guarantees highly accurate 3D measurements without being affected by PCB color or deformation.

This advanced system performs simultaneous 2D and 3D inspection, allowing for a comprehensive analysis of solder paste height, volume, and area. The robust optical engine ensures stable, repeatable results, while the intuitive software reduces programming time to under five minutes.

Why Is Solder Paste Inspection Critical for Your SMT Process?

Solder paste inspection is a key element in achieving zero-defect manufacturing. By identifying printing defects early, the ALD6700S prevents downstream failures and costly rework. Its built-in SPC tools and closed-loop communication with screen printers and pick-and-place machines enable real-time process adjustments.

In addition, the system supports auto-programming without requiring Gerber data, using only a good board sample. This feature, combined with automatic paste-height calibration and intelligent alignment, allows solder paste inspection to become an integrated and autonomous part of your production flow.

With the ALEADER ALD6700S, solder paste inspection

Is no longer just a quality gate — it becomes a proactive control tool that drives efficiency and product quality to new heights.

If you would like to receive more information on solder paste inspection, contact us.

More Information?

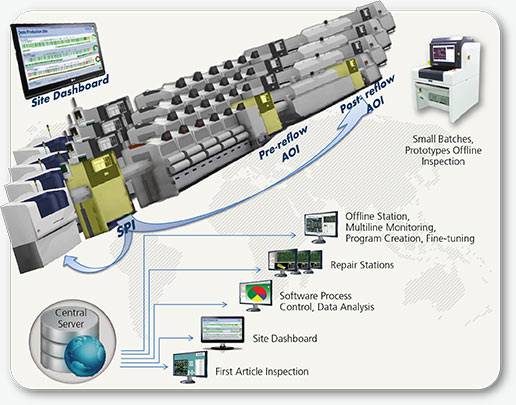

Optical Inspection Solutions

Simultaneous 2D and 3D inspection guarantees full inspection coverage with the most accurate measurement of height, area and volume of the paste deposits

Our Optical Inspection Solutions Consist:

Excellent – high resolution image, generated by the high speed camera and the unique lighting system, clearly differentiate the pastes, pads, silkscreen and the board.

Innovative – automatic warpage compensation and measurement floor recognition method based on the color filter. Effective combination of the high quality color 2D image and large 3D measurement range allows an easy identification of the pads as a zero level for the paste height measurement. The method completely eliminates influence of the PCB warpage. The process is completely automatic and no actions from user are required.

Precise – height measurement based on Phase Measurement Profilometry (PMP). Bi-directional phase shifting projection system ensures accurate and noise resistant measurement of the paste height and volume.