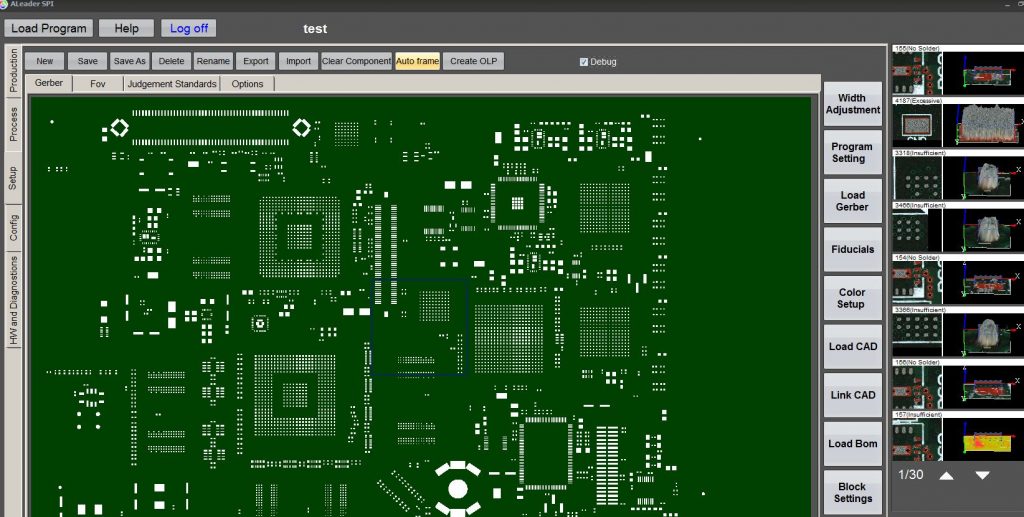

Fast and Easy Programming

It takes just few minutes to create a program on ALeader

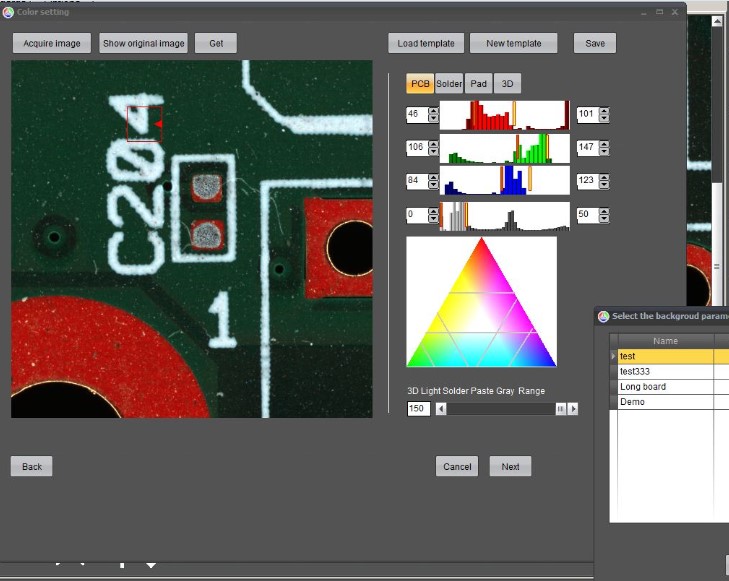

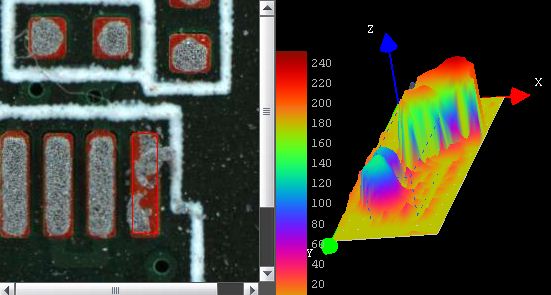

Solder Paste Inspection – SPI system, including the fine-tuning. This is a wizard based procedure, simple and effective – takes less than 30 min to train new comer to program and operate the machine, whether directly on the system or via an offline programming station.

The important point is that the program quality should be independent from the person who creates it. The inspection tolerances must be set according to the factory standards and not according to the experience and understanding of the specific programmer.

ALeader SPI system ensures such independence by allowing setup of default parameters, which are automatically imported into every new program. The idea behind it is that the printing process accuracy and precision requirements are very much depending of the actual paste deposit size.

For instance, applying the paste for micro BGA must be a process with much stricter tolerances compare to the big size pastes of, let’s say, 1206 chip. The tolerances also depend of the stencil thickness, which is actually the ideal paste height.

As it is realized in ALeader SPI, there are default judgement parameters in the config menu, where the tolerances defined for each stencil thickness and the paste size range.

Those standards can be modified only with administrator permissions and normally defined only once – usually during the machine installation. For each new board system automatically sorting all paste deposits according to its size and applies the corresponding tolerances from the default.